Buy..Epoxy

|

|

buy floor epoxy here!

GOOGLE SITE SEARCH - Click here

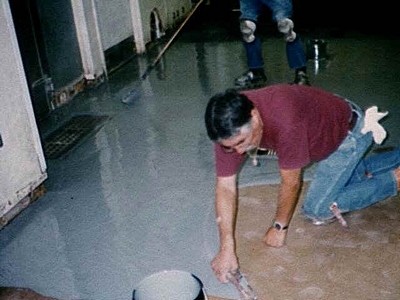

Professional contractors apply our Industrial Floor Epoxy (tm).

Now you can too! catalog page or you can buy now

Goto page two (FLOOR EPOXY PRODUCTS AND LINKS)

EVERYTHING YOU NEED TO KNOW TO UNDERSTAND FLOOR EPOXY RESIN SYSTEMS - READ BEFORE YOU BUY!

Click Here - (www.epoxyproducts.com/datamsds.html) - for Data/MSDS/SDS documents for products sold by PROGRESS EPOXY PRODUCTS.COM

Find the humorous link to the MSDS for COFFEE

Click Here - (www.buy-marine-epoxy-resin.com)

Clicking Here - (www.buy-epoxy-floor-paint.com/msdswater-fixed.pdf)

to view the MSDS for Drinking Water

(note: we actually sell a potable water - standard 61 - epoxy paint - our product is the only one

approved for tanks as small as 50 gallons - all the other potable water epoxies require

tanks of 800 or 1000 gallons - visit www.potablewaterepoxy.com )

Contact page

questions - support - online store link - hours - link to products and prices -

link to internet epoxy search engine - link to home page

Solvent Free or Water - based floor Epoxy?

This website is a small, topic specific, sub-website of our

large primary everything site: EPOXYPRODUCTS.COM

Visit one of our other sub-website pages: buy-marine-epoxy-resin.com

BROWSE WORRY FREE This site is SSL protected/secured

Explore over 80 internet epoxy web sites CLICK HERE to view

epoxy applications, epoxy online stores, how-to articles

Buy..Epoxy

|

|

buy floor epoxy here!

GOOGLE SITE SEARCH - Click here

Professional contractors apply our Industrial Floor Epoxy (tm).

Now you can too! catalog page or you can buy now

|

AN OFFER YOU SHOULD NOT REFUSE Before you buy floor epoxy or anything from anyone, we HIGHLY SUGGEST you CALL 603 435 7199 OR EMAIL US (24/7/365 - except for Sunday morning church fellowship). Let's make sure you have the right products for the job, an understanding of how to use them and a feel for what might go wrong. And if you purchase our products feel free to CALL OR EMAIL US again (24/7/365) before you use them for "tips and tricks" or just some "hand-holding." Perhaps when you're done you'll let us put up some of our pictures on our web site. We have much more information, customer stories, anecdotes, etc. we can share that are not on this web page but might be helpful to you. Email us with your phone # (or call us direct) and we will chat on the phone. You should know your vendor and we want to know our customers. DIRECT EMAIL LINK (CLICK HERE) Most people are not sure what product or products they need to use, how much product they need, and what to expect when using those product(s). You cannot get that from just reading a web site and most web sites just want you to order their product on-line and then go away. We're different. Please call or email us so that your project goes smoothly and it is Win-Win for everyone. You're talking with: Paul Oman, MS, MBA -- Member since 1994: NACE (National Assoc. of Corrosion Engineers), SSPC (Soc. of Protective Coatings) -- Technical Help - not sales talk! |

When it comes to floor epoxies, the way to pick/evaluate your

vendor/supplier is not by what they tell you but by what the don't tell you

Putting down an epoxy on a cement floor can be tricky and lots of things (some outside of your control) can go wrong, almost all of which have nothing to do with the epoxy (so not the vendors' responsibility). Informing you of possible problems and possible ways around those problems could cost the vendor your business and send you off to a more 'cheerful and happy (and cheaper)' floor epoxy vendor web site. An example is an epoxy primer under the epoxy floor paint. It some situations it could save your butt, but more likely you'll just go to a site that doesn't mention using a primer (thus saving you money and time - but also a flooring failure).

1) There are water based floor epoxies and solvent free (sometime solvent based) floor epoxies. Some vendors don't explain the differences and use those differences to to make their product sound so much better (when it is an unequal comparison).

2) Epoxies yellow in sunlight (UV) and over time, especially the non-water based epoxies. This should be make know to you up front.

3) If your concrete is weak or crumpling (lots of dusting) - it could be your surface is not a good candidate for an epoxy floor, or at least one without a primer to 'firm' up the surface. Does your vendor mention weak or dusty concrete?

4) Lots of cement floors do not have a vapor barrier under them and those floors may have water - dampness issues (especially in below grade basement situations). Moisture issues under, on, and inside the cement could make an epoxy coating job a potential failure (there are some things you can try). You should be informed of this possible issue.

5) Many cement floors are full of air (cement can be like a sponge) and as the day warms the air in the cement expands and forms bubbles (popped or unpopped) in the starting-to-harden epoxy. The result is a disaster. Where you warned that this could happen? Diid they suggest fixes if your concrete has lots of air?

6) Old oil and grease stains can cause epoxies to peel right off. You may never be able to remove and degrease these areas no matter what you do to clean them. You should know this up-front.

7) Finally, do these vendors rely to emails or phone calls during the evening or on the weekends when you are working on your floor? Shoot them an email on Friday night and see if you get a reply before Monday or ever.

|

Why You Don't Want, Or Need, A Cycloaliphatic Epoxy Floor Paint - as promoted by one epoxy floor vendor |

What To Watch Out For From Epoxy Floor Vendor Sites:

Best advice from an Epoxy PRO on how to avoid a $$$ DIY epoxy floor disaster

(you won't learn this on any other epoxy floor site)

If any of the following apply or might apply to you:

1) no vapor barrier, or don't know if there is a vapor barrier under your slab; 2) suspect there might be moisture issues in/on the slab; 3) suspect the concrete was not 'vibrated down' and contains lots of air spaces (which can cause bubbles and blisters in the wet epoxy); 4) cannot professionally prep the floor (usually means a shot blast contractor); 5) any existing coating on the floor is peeling and lifting; 6) the concrete seems dusty, gritty, weak or crumbling; 7) you are worried about "hot tire pickup" lifting off your epoxy floor; 8) you have oil stains on the floor (especially OLD oil stains).......

If so, consider putting an inexpensive epoxy primer / sealer (such as ESP 155 - which is an Internet Favorite epoxy coating - not for sale in California) on the entire floor or over those potential trouble spots. Then wait a few weeks or months and see what happens. If everything looks great it is very likely that a 'fancy' epoxy top coat will be successful and probably issue free. You might even decide to just keep the sealed floor and skip the thicker mostly decorative (or at least thicker and pigmented) epoxy top coat (such as 0% VOC INDUSTRIAL FLOOR EPOXY).

If problems developed with the thin, nearly clear ESP 155 epoxy sealer, it is not that big a deal. No worse than having some deck/porch enamel paint lift and peel. You won't trip over it, it is not so 'in your face', and you saved big $$$ that you would have spent on the epoxy, paint chip, top coat. Some existing concrete surfaces are just not good candidates for an epoxy coating. QUESTIONS? email OR call 603 435 7199. Floor Links Page. Learn all about epoxy floors.

Quick Start to Understanding

Epoxy Floors

The most simple epoxy floor 'system' has you clean and

sweep your floor, roll down the epoxy and perhaps throw down some colored chips

on top (or some non-skid grit). Most box store and internet epoxy floor

web sites fall into this category. The system generally works, but it is not how

a professional contractor would do an epoxy floor.

At the other end of the extreme is the following:

renting a floor grinder to grind 'open' the floor and remove old coatings, or a

shot-blast machine for the same thing. Other prep methods might include acid

etching, high pressure water etc. These do nothing for grease and oil stains

which you might never get clean enough for the epoxy to stick over them.

Next in the 'extremely professional' approach is an

optional concrete internal sealer to help control moisture in the concrete,

followed by an optional epoxy primer (either a water based epoxy or a solvent

thinned epoxy). Then the working coat of water or solvent free epoxy paint.

Colored chips are added into a middle clear coat of either clear epoxy or clear

polyurethane. Then a sealing coat of clear polyurethane (The best are 2 part

polys with massive uv blockers to keep the epoxy (clear and pigmented) from

yellowing in the UV light (these special 2 part polys - like our acrylic poly uv

plus - are similar to auto clear coat and have uv blockers). Our acrylic poly UV

plus cannot be sold in Calf . 99.9% of clear 1 and 2 part polyurethanes do not

have substantial UV blockers.

Issues you have to consider include:

1) how much surface prep you are willing to do.

2) how much money and time (and layers of coatings) you

are willing to deal with?

3) which kind of epoxy you want to use - water based,

solvent free, (we offer the only epoxy floor coating with non skid grit mixed

in). It may be too hot to apply some types in summer.

4) the amount, size, and colors of the colored paint chips

if you go this route. (we are the only ones that send you to the 2 paint chip

manufacturers to buy direct). How much of the floor do you want covered in

chips? 5%, 25 % 100%??? There are DIY alternatives to the chips such as flicking

paint droplets onto the floor.

5) do you put the chips directly upon the colored epoxy or

do you put them into a clear epoxy middle coat, or a 2 part poly middle coat?

Clear epoxies will yellow so if you put paint chips into a thick clear epoxy

middle coat )you need special uv protection on top. Using the clear epoxy puts

the chips into a thick middle coat instead of thin middle coat giving a

different look and texture.

6) many concrete surfaces are full of air and if you apply

the epoxy at the wrong time the epoxy will be covered with bubbles and

popped bubbles with razor sharp edges. (usually only an issue when the cement

was poured NOT by a professional concrete vendor who uses special machines to

get the air out of the wet concrete).

7) the often used clear top coat is an issue too. Good

ones cost too much for use in mass market floor kits and the 'auto clear coat'

grade is hard to find and $$. Do you really need one?

8) hard working floors with forklifts and other heavy

tools need an epoxy floor fully saturated with sand or aluminum oxide so that

the quartz sand grains, and not the much softer epoxy resin, is supporting the

load and drag of the heavy equipment. - this is the other extreme from an epoxy

floor just to keep dust and dirt down and hide a few cracks.

1) epoxies that require a wait time after mixing and before applying are almost always obsolete, low quality products.

2) be wary of companies that don't tell you what kind of epoxies they are using and/or imply that their 'method/product' is the ONLY way to go.

3) be wary of companies that downplay surface preparation and don't mention the issues/problems (like yellowing or air bubbles from the cement/concrete) that might be encountered.

4) professionals use technical product data sheets and government required MSDS (material data safety sheets) to learn about and evaluate products. Be wary of companies that do not easily make these available to you as they are probably hiding something they don't want you to know.

5) Email or call the companies involved before you buy. If they will not return an email or telephone call before the sale, you can be certain they will not after the sale.

|

Why You Don't Want, Or Need, A Cycloaliphatic Epoxy Floor Paint - as promoted by one epoxy floor vendor |

|

Cement slab sealers (internal and surface), primers, tie coats help to increase the odds of a successful floor coating project. Read about the two products we recommend CLICK HERE |

|

You can also use REGULAR EPOXY PAINTS instead of EPOXY FLOOR PAINTS on your floor REGULAR EPOXY PAINTS are a bit thicker and can also be used on vertical surfaces. Gray Corro Coat FC2100A epoxy paint is kevlar (tm) reinforced. White or Blight Blue Water Gard 300 epoxy paint if often used in sewers and water treatment plants. CM 15 (ivory or black) is an epoxy paint with a long pot life (for hot weather) and a bit of flex. Originally designed for the inside of gasoline storage tanks on the Gulf Coast. |

An epoxy floor coating can be a one to seven coat system. It can include colored sands or colored chips incorporated into the floor system for looks and/or anti slip. The introduction of sands or chips into the project greatly increase the options and decisions to be made. There are several different methods for how such systems can be applied which will change the number of layers or coatings applied as well as the use of non epoxy coatings in some of those coating layers. Unless the vendor/applicator/contractor offers a 'cookie cutter' approach to epoxy floors, you'll have lots of decisions to make.

If you decide to add 'grit' for anti slip purposes, this also introduces more options for you to consider. There

are different kinds of grits, different sizes of grits, different methods of applying the grit, and different personal

opinions regarding how much grit to use.

Solvent Based Epoxy Floor coatings - Sort of like an oil based enamel, these epoxies contain solvents. These kinds of epoxies are generally not very common any more.

Solvent Free Epoxy Floor coatings - The classic epoxy floor - thick enough to hide many floor flaws. Short working time per batch. Usually no odor. THE EXPERT'S PICK - #1 RATED/BEST SOLVENT FREE FLOOR EPOXY PAINT - CLICK HERE .

|

WATER BASED (WATERBORNE) EPOXY FLOOR PAINTS

|

SOLVENT FREE (or low solvent) EPOXY FLOOR PAINTS |

|

(comparison table) Water Bond Epoxy (tm) med. gray only |

(comparison table) Industrial Floor Epoxy (tm) light gray or beige only |

|

* actually contains voc solvents plus water (restricted in some locations) * slight odor * very long pot life * water clean-up * large coverage per gallon * good color stability * very thin coating - will not hide flaws (may highlight them) * somewhat breathable and some penetration into concrete (good adhesion) * generally less used than solvent free epoxy floor paints * can be primer /sealer under other epoxy (non epoxy) floor systems

|

* no solvents or

VOC issues (solvent free only) * generally odorless * wet thickness equals dry thickness (no shrinking) * thick coating hides flaws and imperfections * can trap air bubbles from expanding air in concrete * shows epoxy yellowing in UV * coverage about 150 sf per gallon * creates vapor seal (radon etc) * can have adhesion issues on damp moisture rich surfaces * tough and durable * standard commercial - professional floor solution * short pot life - working time * use with colored chips or colored sands * works with chips - sands - multi-coat systems |

|

FIND WATER BOND EPOXY IN CATALOG ASK PROFESSOR E . POXY (help link) PROGRESSIVE EPOXY POLYMERS, INC (SINCE 1992)

|

FIND INDUSTRIAL FLOOR EPOXY IN CATALOG ASK PROFESSOR E . POXY (help link) PROGRESSIVE EPOXY POLYMERS, INC (SINCE 1992)

|

|

High Quality Commercial Grade DIY Floor Project "I have been looking for a good Commercial grade garage floor Epoxy system with color flakes and had a hard time till I stumble onto your web site. Most of the product that I find out there are the lower grade product that I’m not interested on, by the way this is for my own personal use in my 550 square foot, standard two car garage, that is the reason I want a good system. I understand I can purchase from you such products. I will need some advise on what you’ll recommend based on my needs. I see you carry two types of epoxy at two different prices. Please I would greatly appreciate if someone could get back to me with the type of product and all the necessary material to do an epoxy flake floor system with a clear top coat finish. Thank you." - Franco 1/15 Thank you for the kind email. The simplest system is simply to roll down a coat of epoxy and sprinkle some colored flakes on top of it. You are wise to seek a more commercial/professional system, but still within a DIY budget and skill set. Here is a suggest system (with a few options included): 1) Surface prep: folks go from simple sweeping to Shot Blasting or Grinding. Each floor is different and some floors are not suitable for coating no matter how you attempt to prepare it. We cannot make official recommendations - it is truly your call, but check out our page on surface prep.

2) Epoxy primer: epoxy floor primers are optional and most floor epoxy manufacturers do not require or sell them. That said, many (not all) experienced epoxy floor contractors recommend or require it. They claim better results, better bond, etc. Consider it extra insurance for a problem free project. You might prime and wait a few weeks before continuing. If bad stuff happens (peeling, lifting, bubbles, etc.) it is only the thin coat of primer involved. Recommended primer ESP 155 1/2 gal unit covers about 150 square feet (not for sale in Southern California). Order 4 units for your 2 car garage.

3) Roll down a coat of solvent free Industrial Floor Epoxy. A 1.5 gal unit will cover just under 200 square feet. Colors are light gray or beige. Order 3 units for your 2 car garage. apply with a short roller. Order 2- 4 rollers. Let the epoxy cure for one or more days.

4) Order colored chips direct from the chip manufacturer. You pick color and percent of each color. 100% chip coverage requires 1 pound of chips per 7-10 square feet. That said, most 2 car garages use two or three 10 pound bags of chips. Order chips direct from Chips Unlimited.

5) Next a clear middle coat of epoxy or polyurethane is applied and the chips are sprinkled onto the wet coating and then application roller is rolled over the chips and coating (called back rolling). The roller picks up the chips and re-deposits them. Add more chips as needed, fix mistakes with a paper towel wipe-up. Epoxy middle coat: thicker, no odor, but all epoxies yellow without special top coating. Two part poly middle coat: thin to start with, but also roll on thin not thick, smelly, leaves some texture from the chips, not for sale in California, doesn't yellow. If using epoxy - Order 4 units of Low V Floor. If using 2 part poly - Order 2 - 3 units of Acrylic Poly UV Plus 2 part poly. Note that the added materials for the epoxy middle chip coat add about $400 to the total cost compared to the Acrylic Poly Plus middle coat.

6) The clear topcoat over the chips in step 5 is the same Acrylic Poly UV plus. Two coats rolled on thin if going over an epoxy/chip, middle coat. Order 4 units of Acrylic Poly Plus (2 coats). One or two coats if going over the same Acrylic Poly UV plus used with the chips in the middle poly/chip layer.

LOTS OF ADDITIONAL EPOXY FLOOR INFO - ARTICLES - WEB SITES - AT THE EPOXY FLOOR LINKS PAGE PRODUCT SUMMARY - 2 part poly middle coat with chips: 4 units ESP 155 primer; 3 units Industrial Floor Epoxy; 4 units Acrylic Poly UV Plus; optional short nap rollers (2-4) for the Industrial Floor Epoxy layer.

PRODUCT SUMMARY - Low V Floor clear epoxy middle coat with chips: 4 units of ESP 155 primer; 3 units of Industrial Floor Epoxy; 3 units of Low V Floor Epoxy; 4 units of Acrylic Poly UV Plus; optional short nap rollers (2-4)

PRODUCT SUMMARY - 20-30 pounds of chips ordered directly from Chips Unlimited. COST ESTIMATES - (either system) - about $3 to $4 per square foot plus Chips (chips are under $150) PURCHASE ALL THESE PRODUCTS (LESS THE CHIPS) AT OUR THIRD PARTY, PRIMARY STORE CLICK HERE. OR CALL 604 435 -7199 |

Epoxy Floor On Large Garage - primer/base/chips/clear coat

About 1600 sf business floor -

used Esp 155 primer sealer, 15 gallons of Industrial Floor Epoxy

and Acrylic Poly UV Plus two part clear epoxy topcoat. Chips

purchased direct from Chipsunlimited.com

"Good afternoon Paul! My floor is done and it is all over but the smell from the two part polyurethane top coat.

. HA! Cool temps worked in my favor to keep pot-life long but the rainy weather tried to work against me. I ended up tarping over my garage door opening so I could get the area under the seal done without dealing with water on the floor. A cheap rubber squeegee from Harbor Freight was an essential item because it is way too tough to get even distribution of the industrial floor epoxy with just a roller. The squeegee was the same price as a single 24" roller tube anyway and it worked great. I ended up broadcasting chips into the epoxy rather than the clear coat because I wanted a slightly smoother floor. It probably took more chips this way but I think it was a fair trade.

If I had to do it over again I'd seriously consider putting chips into a clear epoxy middle coat because even with two coats of poly my basement floor is a bit rougher than I thought it would be. I ended up putting a third coat of UV Poly on the garage floor and it still seems pretty non-skid but is smooth enough that it will be easier to keep clean.

The coverage estimates were spot on for Floor epoxy and UV Poly top coat. The Primer was another story, my basement floor was pumped concrete and after bead blasting it was like a cement sponge! The poured concrete on my mail level took the primer as expected.

I'm very happy with the results and will be ordering another gallon of UV clear from you when it is time to do the steps and landings.

Thanks again!" Gordon 4/16

Brent L. who ordered our solvent free, commercial grade, Industrial Floor Epoxy emailed:

"A few weeks ago I ordered epoxy, color chips and UV Poly top coat for my garage (1700 sqf t). You may or may not remember an order of 15 gal of epoxy to Bismarck, North Dakota....

Anyway, I have half the floor done (half because of moving everything in my garage from one side to the other) and the floor looks awesome. People that have seen it are astounded, they've never seen anything like it because no one around here supplies industrial epoxy.

In high school (Calgary, Alberta) I used to work for a company that specialized in epoxy patching of concrete, so I am somewhat familiar with epoxies. I spent many months researching on the Internet what products are available and their cost. The product you have supplied is top notch and I have passed on your name to anyone that is interested."

"Thanks for all your advice, tips & moral support concerning my project. It turned out beautiful. Quality people backing a quality product is the only way to go!" Joe

|

Professional contractors apply our Industrial Floor Epoxy (tm). Now you can too! catalog page or buy now

|

Links to Lots of MUST READ Information Articles About the Best Epoxy Floor Paints, Including Preparation, Alternatives, What Can Go Wrong, etc.

|

|

Bio Vee Seal -

INTERNAL CONCRETE

SEALER |

SOME OF THE SITES THE ABOVE LINK WILL DIRECT YOU TO |

|

Clear Top Coats -

FLOOR CLEAR

TOP |

Best Floor Epoxy -

CLICK

HERE

|

|

Epoxy Quartz Floor -

BROADCAST FLOOR |

Acid Etching -

ACID |

|

Epoxy Paint Chip Floor -

CHIPS |

Epoxy Paint vs. Floor

Epoxy Paint -

EPOXY

PAINTS |

|

Epoxy Paint -

SURFACE PREP |

Floor Basics/Options -

START HERE |

|

Floor Epoxy - CATALOG PAGE |

Questions:

ASK PROFESSOR E. POXY |

|

Epoxy Based Floor Coatings - Sampler Kit Solvent Free Industrial Floor Epoxy - 48 oz test kit of IFF in beige or light gray. Tired of the low end stuff sold in mass market box stores or hard sell epoxy flooring web sites run by a marketing major and staffed with ex-shoe salesman just interested in your money? Check out our industrial - commercial (you can buy 15 gallon units), solvent free, Industrial Floor Epoxy (even the product name is simple, no frills labeling). Use with or without chips (order separately - picking colors and percentages), and with or without clear epoxy or poly intermediate or topcoats. Shop like a Professional - where you pick and select what you need. This product is featured on the Best Epoxies website.

|

DID YOU KNOW...

Epoxy coatings are used because of their

outstanding chemical resistance, durability, low porosity and strong bond

strength.

Epoxies consist of a ‘base' and a ‘curing' agent. The two components are mixed in a certain ratio. A chemical

reaction occurs between the two parts generating heat (exotherm) and hardening the mixture into an inert, hard

‘plastic'.

Epoxies yellow, chalk (or more commonly least lose their gloss), in direct sunlight (UV). The yellowing can

be a real problem. For pigmented epoxies select colors that are dark or contain a lot of yellow (such as green).

Even clear epoxies will yellow and cloud up. Often epoxies are top coated with latex or urethanes that will retain

their color and attractive gloss. This is particularly true if color coding or matching company colors is important.

Epoxies will harden in minutes or hours, but complete cure (hardening) will generally take several days. Most

epoxies will be suitably hard within a day or so, but may require more time to harden before the coating can be

sanded.

By their nature, epoxies are hard and brittle. Additives can be added to epoxies that make them less brittle,

but generally at the loss or reduction of other positive epoxy properties such as chemical resistance.

Other clues of cheap epoxies include ‘induction time' (after mixing the two components the mixture must sit

for several minutes to ‘self cook' before being applied).

The best time to recoat epoxy is within about 48 hours after the initial coat. Because epoxies take days to

reach full cure, a second coat applied shortly after the first coat will partially fuse to the first coat rather

than forming a simple mechanical bond.

End users can thicken epoxy with many things, Tiny glass spheres, known as micro-spheres or micro-balloons

are commonly used. Besides thickening, their crushable nature makes sanding the hardened epoxy easier. On the downside,

they work like tiny ball bearings, resulting is sagging and slumping. Another thickener is fumed silica (a common

brand name is Cabosil (tm)) which looks like fake snow. About 2 parts fumed silica with one part epoxy will produce

a mixture similar in texture and thickness to petroleum jelly. Micro-spheres and fumed silica can be combined together.

Fisheyes are areas on a painted surface where the coating literally pulls away for the substrate leaving a coatingless void or fisheye. Often fisheyes are caused by surface contaminants such as a bit of silicon, wax, or

oil. I have also seen them on clean plywood where epoxies paints have been used as sealers and the problem might

be due to uneven saturation (soaking-in) of the epoxy into the wood. Surface tension plays a big part in fisheyeing.

There are some additives that can be mixed into the epoxy that will reduce surface tension. Likewise, on wood,

applying several coats of solvent thinned epoxy, instead of one coat of unthinned epoxy, seems to work well. Applying

a thick coat of epoxy over a contaminated fisheye surface will bury the fisheye but expect the coating to peel

away in the future. As a rule of thumb, always suspect some sort of surface contamination as the primary cause

of fisheyeing.

Adding a bit of solvent to a solvent based or solvent-free epoxy is something that most manufacturers would

not officially approve of and something that might not work with all epoxies. However, it can be done (unofficially)

with the epoxies I deal with. Adding solvent to these epoxies will: 1) thin them out; 2) increase

pot life; 3) allows

them to flow off the brush/roller a bit more smoothly; and 4) perhaps allows them to ‘soak-in', penetrate, or may

be soften, the substrate just a little bit. Not change is visible in the epoxy unless 12% or greater solvent is

added. With that amount of solvent, the epoxies no longer cure with a glossy finish.

It is best to use epoxies with a mix ratio close to 1 to 1 as opposed to something 4-1, 5-1, etc. because errors

in the mix ratios can be more pronounced with the latter. That said, no matter what the mix ratio is, some epoxies

are more forgiving of mix ratio errors than others. One ‘trick' of epoxy vendors with odd or very sensitive mix

ratios is to sell calibrated pumps that disperse the epoxy components in exact amounts.

How Thick? How thick should your coating be? Economics play a major role in determining how much coating to apply. One U.S. gallon contains 231 cubic inches. That's only 1.6 cubic square feet of surface at one inch thick and that's also assuming a solvent-free product. If the product is 25% VOC (i.e. 25% solvent) then dry thickness/coverage will be 25% less. Again, assuming a 1/4 inch thick coating (250 mils) maximum coverage will still be only 6.4 square feet per gallon. A solvent-free (100% solids) epoxy coating applied at 16 mils will cover 100 square feet per gallon (note: the wall paint in your office is probably 2-4 mils). While thick coatings sound like a good idea, they use so much product that they must be made very cheaply so that coating 1,000 or 10,000 square feet can still be done at a competitive price. A high quality, fairly expensive product with a coverage rate of 100 sq. feet or more per gallon, on the other hand, will have a low enough cost per sq. foot to provide both economy and top quality.

Buy Floor Epoxy at our 3rd party storefront --- ("EPOXY PAINTS" section)

Goto page two (FLOOR EPOXY PRODUCTS AND LINKS)

|

MARINE CATALOG |

HOME/DIY/COMMERCIAL CATALOG |

| Section One TWO PART MARINE EPOXIES- CLEAR EPOXIES |

Section A EPOXY PAINTScorro coat FC 2100; NSP 120; water gard 300; coal tar ; CM 15; crack coat™ |

|

Section Two

FILLERS THICKENERS ADDITIVES fumed silica; microsphere/balloons; poly fibers; copper; graphite; Teflon (tm); wood flour; EZ thick; rock flour

|

Section B FLOOR EPOXIES (regular and non-skid products), SEALERS, ACCESSORIESwater bond (water based); solvent free industrial floor epoxy; bio vee seal; water based floor epoxy, floor epoxy with grit; walnut shell; ground white rubber grit |

|

Section Three

THICKENED EPOXIES - EPOXY PUTTIES, ETC. wet/dry 700; splash zone; quick fix 2300, QR 2400 rubber epoxy |

Section C THICKENED EPOXIES - EPOXY PUTTIES, ETC.wet/dry 700; splash zone A-788, quick fix 2300; QR 2400 (tm) rubber epoxy |

|

Section Four

TWO PART EPOXY PAINTS (barrier coats) corro coat FC 2100; water gard 300; CM 15; EZ Spray; epoxy primer; crack coat™ |

Section D CLEAR TWO PART EPOXIESlow V epoxy; basic no blush; ESP 155; Bio-Clear 810 |

|

Section Five URETHANES AND NON-EPOXY COATINGS Aluthane (aluminum coating); LPU Marine |

Section E NON-EPOXY PAINTS SEALERSAluthane moisture cured urethane; Acrylic Poly UV Plus and other 2 part polys ; Capt. Tolley's creeping crack sealer |

|

Section Six

NON-SKID DECK COATINGS walnut shell; ground white rubber

|

Section F MIX-IN ADDITIVESfumed silica; fiber fill; micro balloons/micro-spheres; graphite; Teflon (tm); copper powder; wood flour; EZ thick, rock flour |

|

Section Seven

MARINE REPAIR PRODUCTS pipe wrap; fiberglass tape (cloth); Capt. Tolley's Creeping Crack Cure |

|

|

Section Eight

MISC. MARINE PRODUCTS short nap rollers; TA 661 (solvent free epoxy clean-up); 1 inch foam brushes; 2 inch bristle brushes; tongue depressors |

|

|

Call (603-435-7199) or EMAIL with questions /phone orders etc. about what you're doing. We try to earn your business one phone call at a time! |

|

| NON STANDARD | FLOOR EPOXIES

|

AND LINKS | ||||

| PENNY FLOORS | basic no blush marine type epoxy | CLICK HERE | ||||

| ============ |

============

|

============

|

||||

| SHIPPING CONTAINER FLOORS | low v clear epoxy | CLICK HERE | ||||

| ============ |

============

|

============

|

||||

| INTERNET FLOOR LINKS SITE | floor links | CLICK HERE | ||||

| ============ |

============

|

============

|

||||

|

"OLD GOAT" FLOOR EPOXY

Q & A |

floor focused help site | CLICK HERE | ||||

| ============ |

============

|

============

|

||||

| FLOOR EPOXY IN ONLINE CATALOG | start shopping here | CLICK HERE |

..........................

SITE SPONSOR LINKS..........................The EPOXY GURU - Internet's most popular epoxy repair/help site. Leave your questions for the everyone's favorite Guru.

7 epoxies/coatings to fix 'darn near' everything - today's best coating technologies

See how Sunken Yacht is saved by epoxies applied underwater